SAF – Submerged Aerated Filters

SAF (Submerged Aerated Filters) is BioKubes preferred technology, especially if the requirement is for reduction of organic material in the water (BOD and COD reduction) or if the requirement is for reduction of Ammonium NH4).

It is not the preferred technology if the requirement are for total nitrogen removal.

SAF is characterized by

- Very stable cleaning process with low requirement for maintenance

- Tolerant towards fluctuations in the incoming water (especially in connection with BioKube’s patented technology)

- Low energy consumption

- Very efficient, with very small footprint.

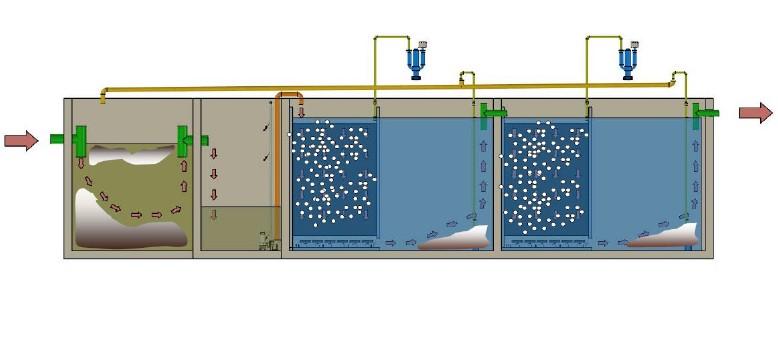

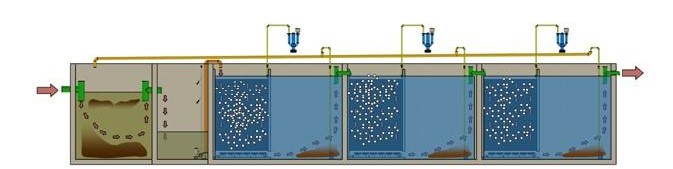

Submerged Aerated filters

BioKube basic technology

No smell from a BioKube

Restaurant on top of a wastewater system?

Since there is no smell from a BioKube system due to the total elimination of hydrogen sulfide, the BioKube wastewater system at a town hall, is used as the floor of the public open-air restaurant.

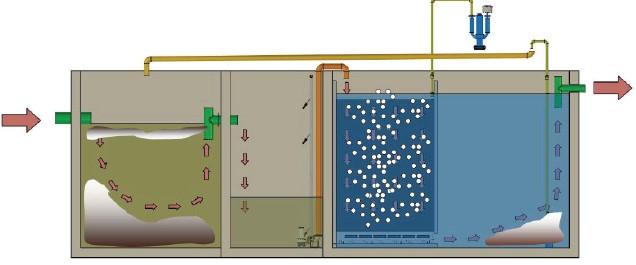

Jupiter one-step system.

With standard household wastewater containing BOD 250 – 400 mg/l, a BioKube one chamber system will treat the water to BOD < 25 mg/l.

The one chamber system consists of:

- Preceding septic tank to retain solids

- Buffer tank to allow for timed inflow of the water to be treated (BioKube patent)

- Aerated zone with the bacteria living on the submerged aerated filters.

- Settling zone to remove suspended solids

- Recirculation from the settling zone to the septic tank. This sends all solids to the septic tank. It eliminates hydrogen sulfide (H2S) – and thereby smell – from the system, because aerated water containing oxygen is sent back to the septic tank.

Jupiter Two-Step System

In a two-step system, the second step will reduce BOD outgoing to below 10 mg/l

This compares to the 25 mg/l incoming from the first treatment step.

Jupiter Three-Step System

The system is installed above ground at Kuala Lumpur Technical University. You can see the steel bars around each of the Jupiter units to take the pressure from the water in the system. If the system was installed inground, these steel bars would not have been necessary.

You can see that each of the three identical steps contains a aerated treatment zone followed by a settling tank to remove suspended solids.

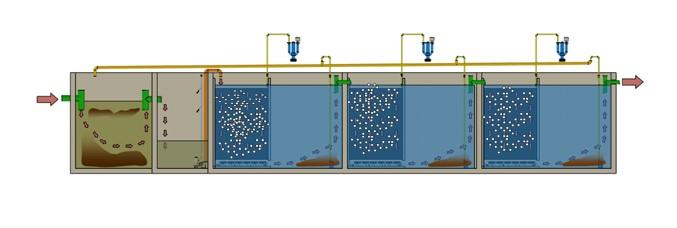

Jupiter Three-Step System

The system is under installation at a campsite in Denmark.

You can see the three Jupiter units and since the system is being installed inground, there is no need to strengthen the system with steel bars.

You can also see the green lid of the preceding septic tank.

Jupiter Three step system

In a 3-step system, the third step will perform nitrification.

In this process Ammonia (NH4) is reduced to below 5 mg/l.

The continued recirculation from the third chamber settling zone will also reduce total nitrogen by ca 50 % through denitrification.

See video of aerated zone in a BioKube Jupiter system

Why choose BioKube?

SAF technology has a stable cleaning process

SAF technology is very stable and is very good at handling fluctuations in the incoming water

SAF systems are easy to maintain

BioKube SAF systems require very little maintenance. A trained technician can based on BioKube service manuals easily maintain the systems.