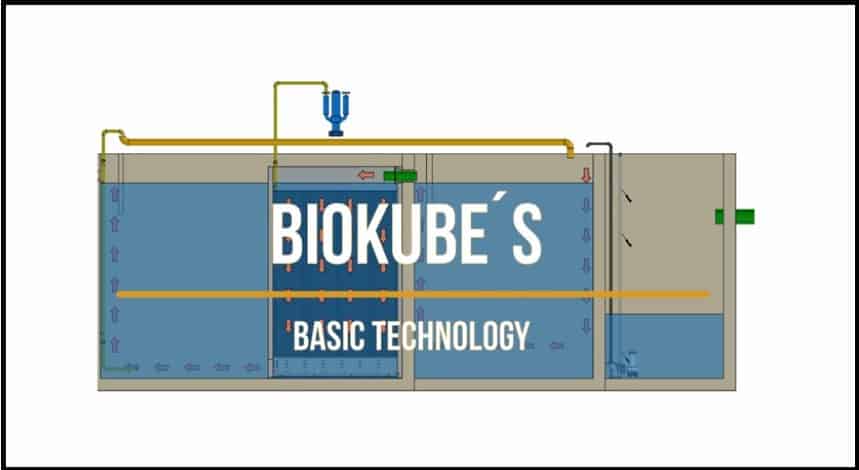

BioKube uses a modular and scalable design

BioKube basic technology of submerged aerated filters built in a number of standard units are easily scalable. Much like children playing with LEGO toy plastic building blocks. If the child wants to build a bigger house, he uses more LEGO blocks.

If you need a bigger wastewater system, you need only more standard BioKube modules.

See video of BioKube basic technology

One technology – many solutions

The picture illustrates how the same basic technology can deliver systems that precisely match the buyers wishes.

The technically same unit can be installed in ground, above ground (strengthen with outside steel bars), in a pre-built concrete tank or in a container for easy relocation.

That the technology is the same means that service is much easier to implement.

Saturn System – above ground

Saturn system in Australia.

Being installed above ground, the system needs to be strengthened with outside steel bars to take the water pressure.

On the other hand, an above ground system reduces cost of ground work.

BioContainer 20-foot

The picture shows a BioContainer system under production.

You see the two separate units, septic tank and treatment units. Both are ready for mounting in the 20 foot container.

Jupiter system – Inground

The picture shows a Jupiter system under installation in Denmark.

Since the system is installed inground the water pressure is absorbed by the outside earth and there is no need to use steal bars for strength. This saves cost.

BioContainer 20-foot

The picture shows a BioContainer system under production.

The white plastic box is installed in the container and awaits mounting of inner parts like BioBlocks, pumps and blowers.

To take inside water pressure, the walls are strengthened with steel bars.

BioContainer 40 foot

The picture shows a BioContainer system under production.

You see the two separate units, septic tank and treatment units. Both are ready for installation in the 40-foot container.

You can see the steel bars on the outside to take the water pressure.

Why chose BioKube?

One common technology reduces time required for training

The service and maintenance of a BioKube system is in many respects the same despite difference in size

Many standard modules make precise design easier

It is quite simple. If you need to treat more water; add an additional module